Boosting Efficiency and Reliability: How Reciprocating Compressors Can Enhance Your Operations

This article has everything you need to know about reciprocating compressors and how enhancing your operations is made possible. Get to know if this is the best type of compressor suited for your needs. And you’re all set!

Are you looking into getting your operations a fine upgrade? Here, you will get to know possible and viable solutions that you can take into consideration in terms of industrial refrigeration and freezing, heat pumps, and gas markets. Keep reading and let’s dive right in!

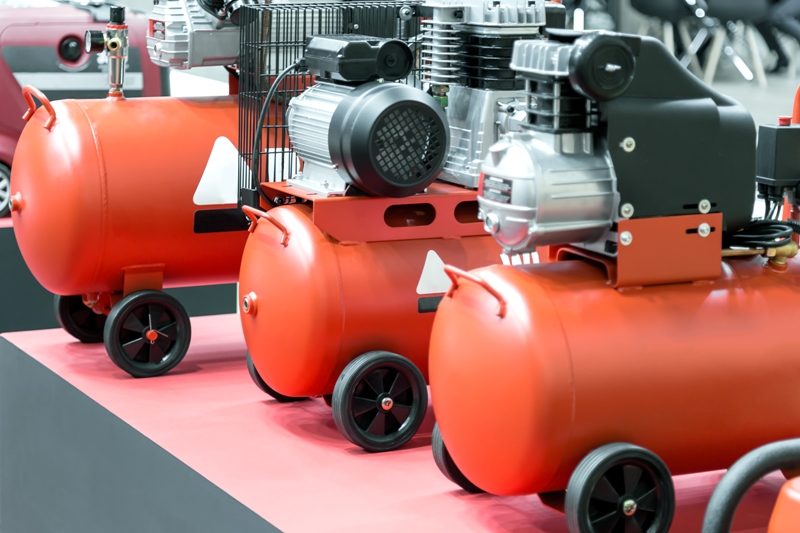

What are Reciprocating Compressors?

The term Reciprocating Compressor, came from how it is operated which is literally through a reciprocating movement. When we talk about reciprocating compressors, it is used to increase the pressure of a gas by reducing its volume. They are commonly used in applications like refrigeration, natural gas processing, petrochemical industries, and air conditioning. Adding this into your application gives high advantages when it comes to the efficiency of the operation, hence, why many people look into utilizing this.

How this works is to follow through the 4 stages of compression – compression, discharge, expansion, and intake.

Compression – From the term itself, this is where the gas is compressed. How this happens is the piston moves upward which makes the volume of the cylinder decrease leading to an increase in pressure.

Discharge – After the gas reaches the desired pressure, the discharge valve opens up and allows the compressed gas to exit the cylinder.

Expansion – Here, a small volume of gas expands slightly below suction pressure from the clearance socket. Then, the discharge valves close, and the piston retreats to its original place.

Intake – Lastly, the intake stroke happens when the piston moves downward, creating a vacuum in the cylinder that causes the gas to enter due to the pressure difference.

How do Reciprocating Compressors boost efficiency?

Reciprocating compressors have several things to take note of for you to reach the right amount of efficiency. Factors that affect this are the following:

Firstly, their design allows for precise control over compression processes. How reciprocating compressors were designed can let you fine-tune features like speed, stroke, and discharge pressure for optimum results. Also, this design can achieve high compression ratios that allow the compression of gases to reach high pressure which saves a lot of energy usage.

Secondly, reciprocating compressors in comparison to other compressors experience notable efficiency losses at lower demand levels. Reciprocating compressors can maintain their overall prime productivity.

Lastly, reciprocating compressors have exceptional durability and longevity adding to their appeal. Although, maintenance is a great part of any type of compressor. If you properly maintain them they can operate well for extended periods compared to others.

So, if you are looking for a reciprocating compressor brand that leverages thermal technology developed through years of experience to consistently provide high-quality effects. Check out MYCOM compressors which have been highly trusted globally for over 70 years now. Have a chat with their consultants to get the best plan and prices in the market.