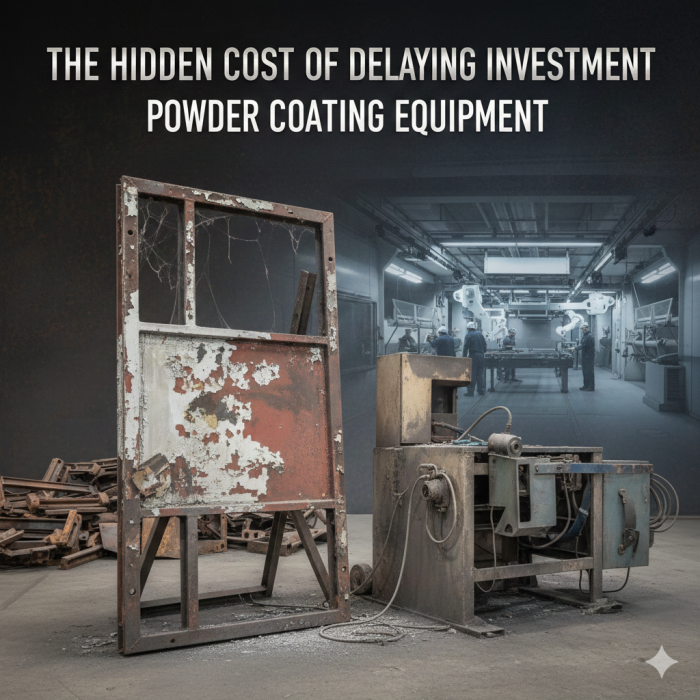

The Hidden Cost of Delaying Investment in Powder Coating Equipment

Capital decisions inside a finishing operation rarely feel urgent until performance starts slipping. Equipment that still turns on can quietly drain margin, time, and opportunity long before it fully breaks down. Delaying upgrades in powder coating equipment often costs far more than the price tag suggests.

You Might Be Missing Faster Production Cycles Without New Gear

Older coating lines were built around slower cure times and longer changeovers. Manual adjustments, uneven heat distribution, and limited automation all add seconds and minutes to every batch. Over the course of a week, those small delays compound into hours of lost production.

Newer powder coating systems are designed to shorten dwell times and speed up transitions between jobs. Modern powder coating ovens heat more evenly and recover faster between cycles. Shops running outdated equipment often underestimate how much throughput they sacrifice simply by sticking with familiar processes.

Lost Revenue from Jobs You Can’t Take on Due to Limits

Capacity limits do more than slow output; they cap growth. Aging powder coating equipment may restrict part size, weight, or volume, forcing shops to turn down profitable work. Those missed opportunities often go straight to competitors with newer capabilities.

A modern powder coating equipment package expands what a shop can confidently quote. Larger chambers, higher airflow, and better controls allow operators to accept complex or high-volume jobs without risk. Delaying investment quietly shrinks the range of customers a business can serve.

Higher Maintenance Bills on Aging Coating Equipment

As equipment ages, maintenance shifts from preventive to reactive. Replacement parts become harder to source, downtime stretches longer, and emergency repairs disrupt schedules. Maintenance budgets creep upward without delivering any performance improvement.

New powder coating equipment is built with reliability and service access in mind. Updated components reduce wear points and simplify routine service. Shops often discover that maintenance savings alone offset a portion of the cost of powder coating equipment for sale within the first few years.

Quality Hits That Turn Customers Toward Competitors

Finish quality depends heavily on consistent application and cure. Older powder coating ovens struggle with temperature swings, cold spots, and uneven airflow. These issues show up as color variation, poor adhesion, or premature failure.

Customers notice when coatings chip, fade, or wear faster than expected. Once quality slips, repeat business becomes uncertain. Investing in modern powder coating systems protects finish consistency and preserves customer trust that took years to build.

Energy Waste from Less Efficient Old Machinery

Legacy coating equipment consumes more energy than most operators realize. Older burners, inefficient insulation, and outdated controls waste heat and electricity during every cycle. Utility bills rise quietly, often accepted as a fixed cost of doing business. Modern industrial powder coating oven designs focus on energy efficiency. Improved insulation, airflow management, and smart controls reduce fuel use without sacrificing performance. Over time, energy savings become a measurable return on upgrading rather than maintaining outdated machinery.

Missed Efficiency Gains That Cut Labor Costs

Labor efficiency often suffers when equipment requires constant attention. Manual adjustments, frequent monitoring, and workarounds pull operators away from higher-value tasks. Staffing costs rise while productivity stays flat.

New powder coating equipment integrates automation that reduces hands-on time. Programmable controls handle temperature, timing, and airflow adjustments automatically. These gains allow teams to do more with the same headcount instead of adding labor to compensate for outdated processes.

Fewer Repeat Orders Because Finishes Don’t Hold up

Coating durability directly affects customer loyalty. Finishes that fail prematurely lead to complaints, rework, or warranty claims. Even if the shop fixes the issue, confidence is already damaged. Advanced powder coating systems provide better cure control and repeatability. That consistency improves long-term finish performance in real-world conditions. Stronger, longer-lasting coatings encourage repeat orders and referrals that aging equipment struggles to support.

Why Waiting Costs More than Upgrading Sooner

Delaying upgrades often feels like a safe financial choice, but the math rarely supports it. Lost productivity, higher maintenance, energy waste, and missed revenue accumulate quietly. By the time replacement becomes unavoidable, the total cost far exceeds the price of upgrading earlier. Evaluating powder coating ovens and powder coating equipment packages sooner allows shops to plan rather than react. Options such as a powder coating oven for sale can be matched to actual production needs instead of emergency timelines. Strategic investment stabilizes operations instead of forcing rushed decisions.

Reliant Finishing Systems solves production bottlenecks by engineering powder coating solutions that align with how modern shops actually operate. Their equipment is designed to improve throughput, finish consistency, and energy efficiency without forcing unnecessary complexity. By focusing on long-term performance and scalability, they help manufacturers replace hidden costs with measurable gains.